Many fluids are used in the production of metal parts and components. Komline’s filtration solutions extend the longevity of equipment which requires these fluids and allow manufacturers to reuse fluids, reducing costs and waste.

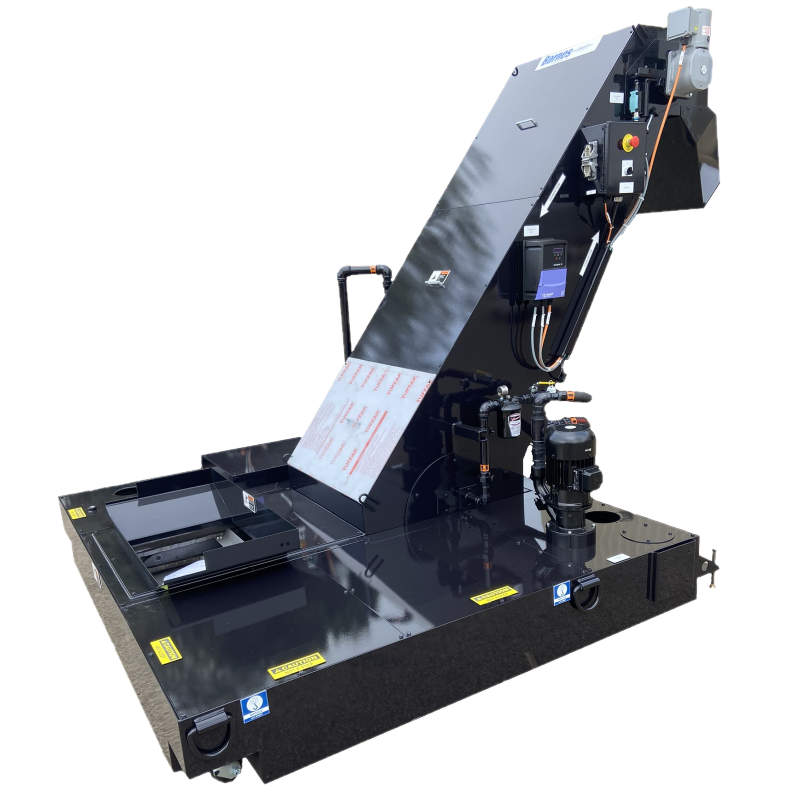

Coolant Processing & Filtration

During manufacturing processes for metal removal, coolant is required to keep the tool and workpiece from overheating, ensuring consistency and quality of the final product. By filtering coolant, contaminants and debris can be removed from the coolant, allowing the coolant to be recycled.

Filters designed and produced by Komline are used across different manufacturing industries, including automotive, aerospace, and general machine tooling to reuse coolant and extend the life of equipment.

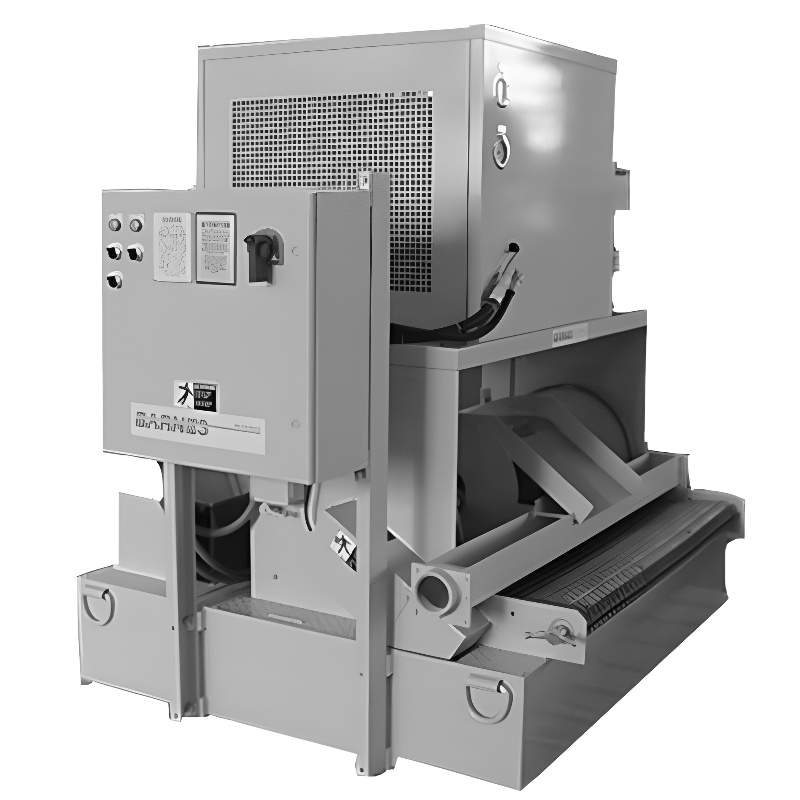

Metal Processing

The production of metal products, including pipe and rolls, requires coolant and wash fluid. By recycling these fluids, producers can reduce both costs and waste output. Filtration of the fluid also ensures consistent quality.

Filters designed and produced by Komline allow for the reuse of fluids and ensure the longevity of equipment.

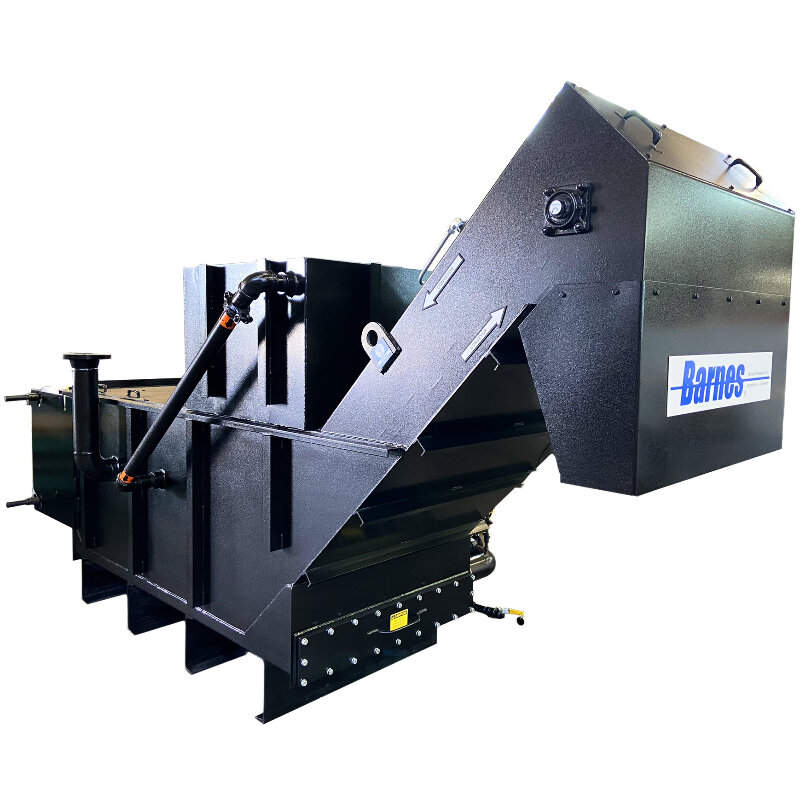

Parts Washing

Parts washing is an important step in the production of many components. The parts washing fluid can be filtered to remove contaminants and debris, allowing the fluid to continue to be useful.

Komline's filters can extend the life of parts washing fluid, lowering both costs and waste output. Due to the importance of parts washing, these filters can be used across many industries.