Applications

Related Products

Benefits

Quick Investment Return

Savings from increased production, lower maintenance costs and effective coolant re-use, return original investments in a short period.

Lower Costs

Operations:

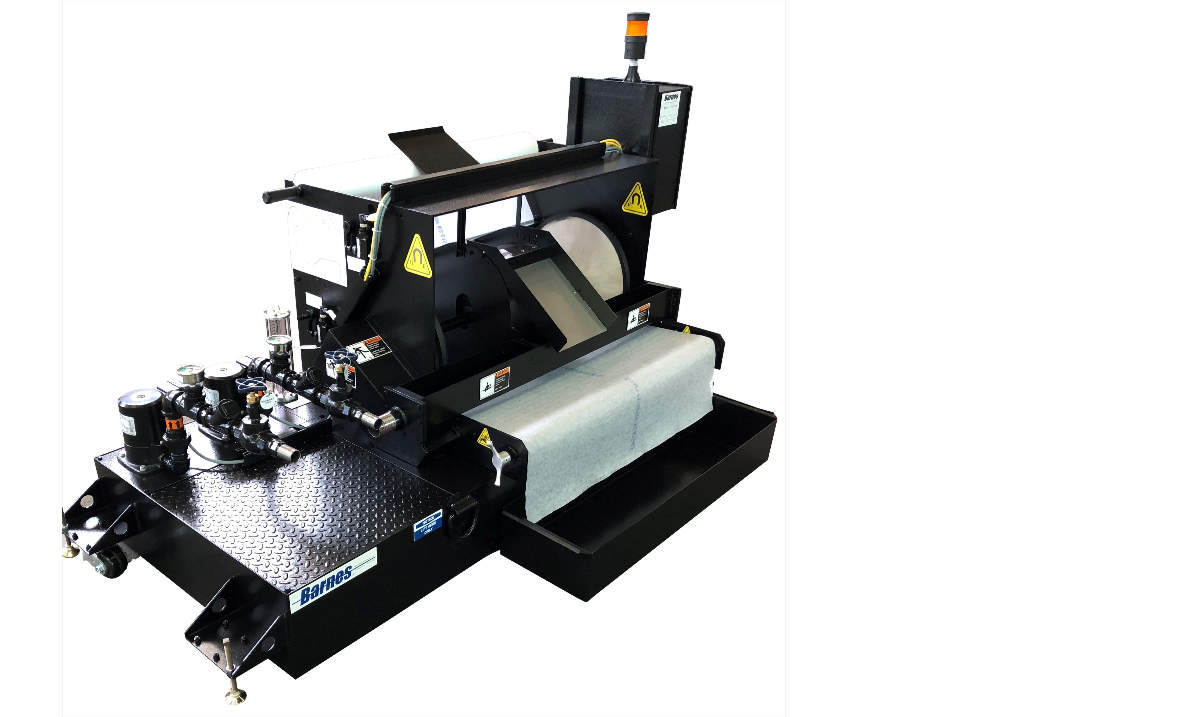

Contaminants are removed automatically. Coolant does not have to be discarded due to heavy overload of chips and grit.

Maintenance: Time and labor savings design of machines facilitates maintenance. Merely empty the conveniently located sludge pan. Replacement of fabric rolls is quick and simple.

Increased Production

Better Finish Control – Efficiency results in fewer rejects related to coolant; reduced downtime for machine cleaning and maintenance.

Increased Machine Efficiency

With clean coolant, abrasives (grinding wheels, abrasive belts, honing stones, etc.,) do not become loaded with waste particles. Dressings or replacement are less frequent. Load-free coolant spray leaves no abrasive deposits on machine surfaces, fixtures, tables and critical working parts.

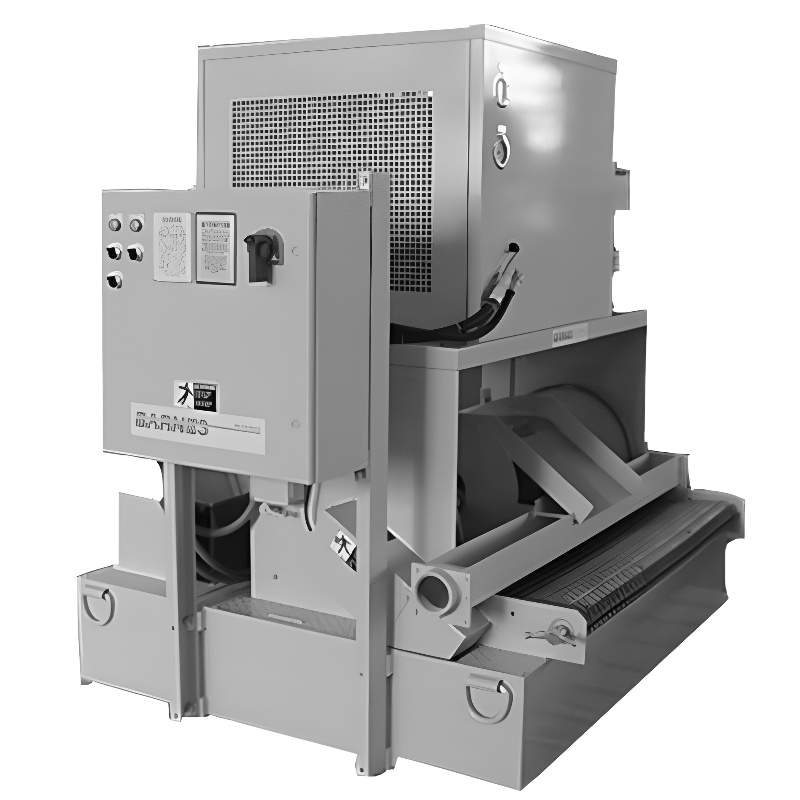

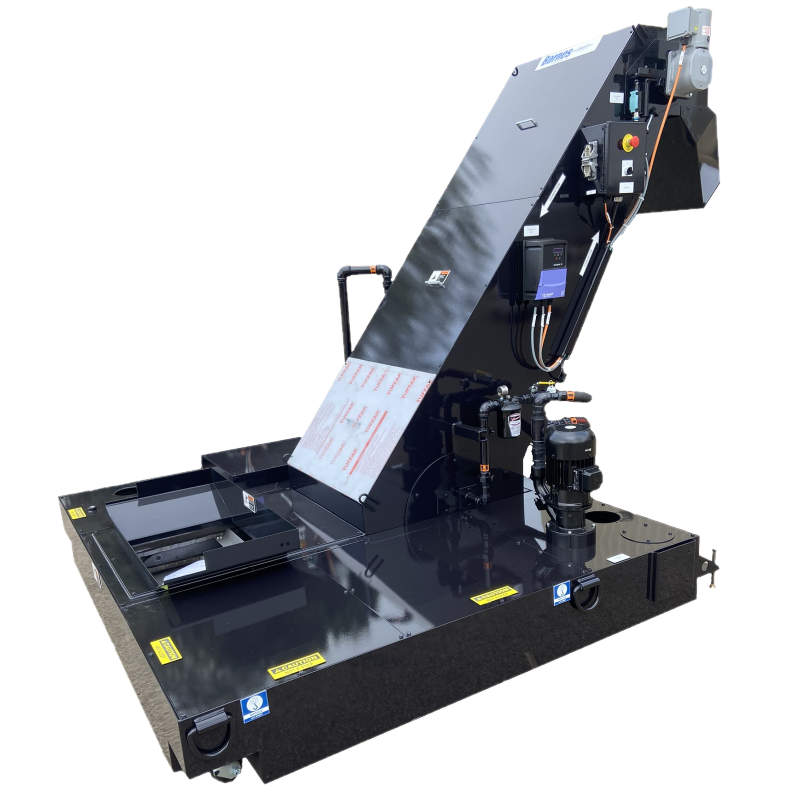

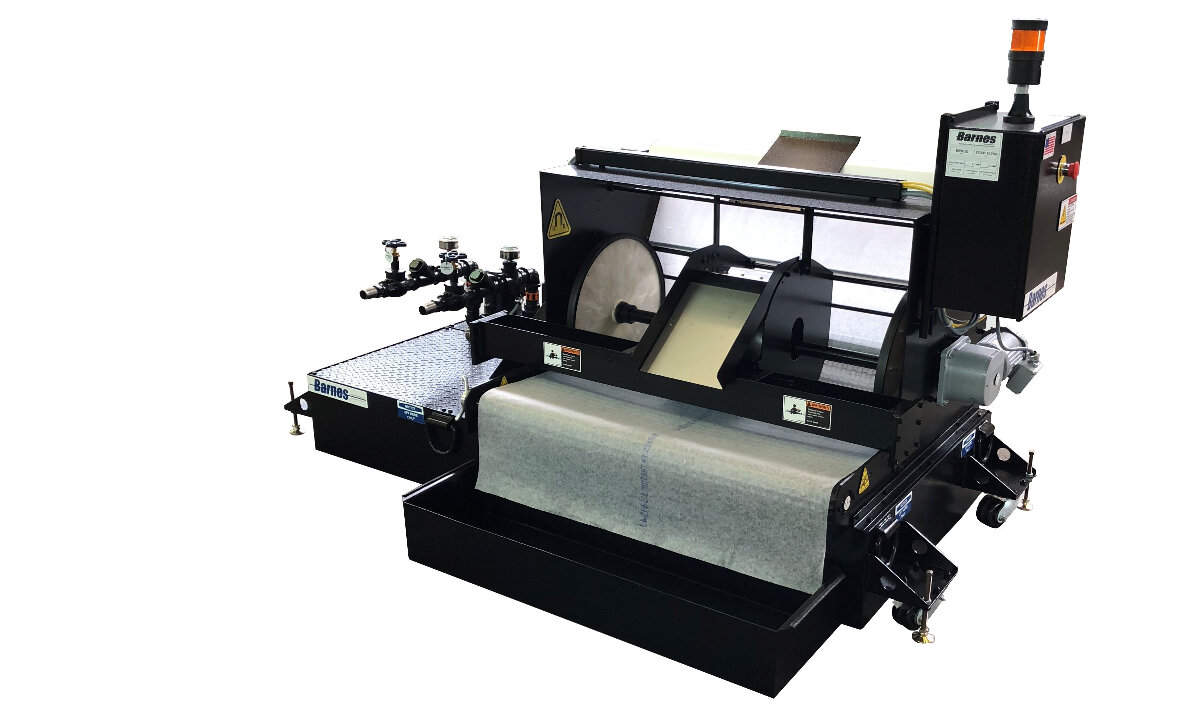

Compact Design

Requires less floor space. In many cases, the low profile eliminates the need for a pump back.