Applications

Related Products

Benefits

Install

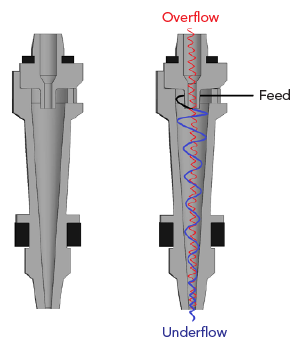

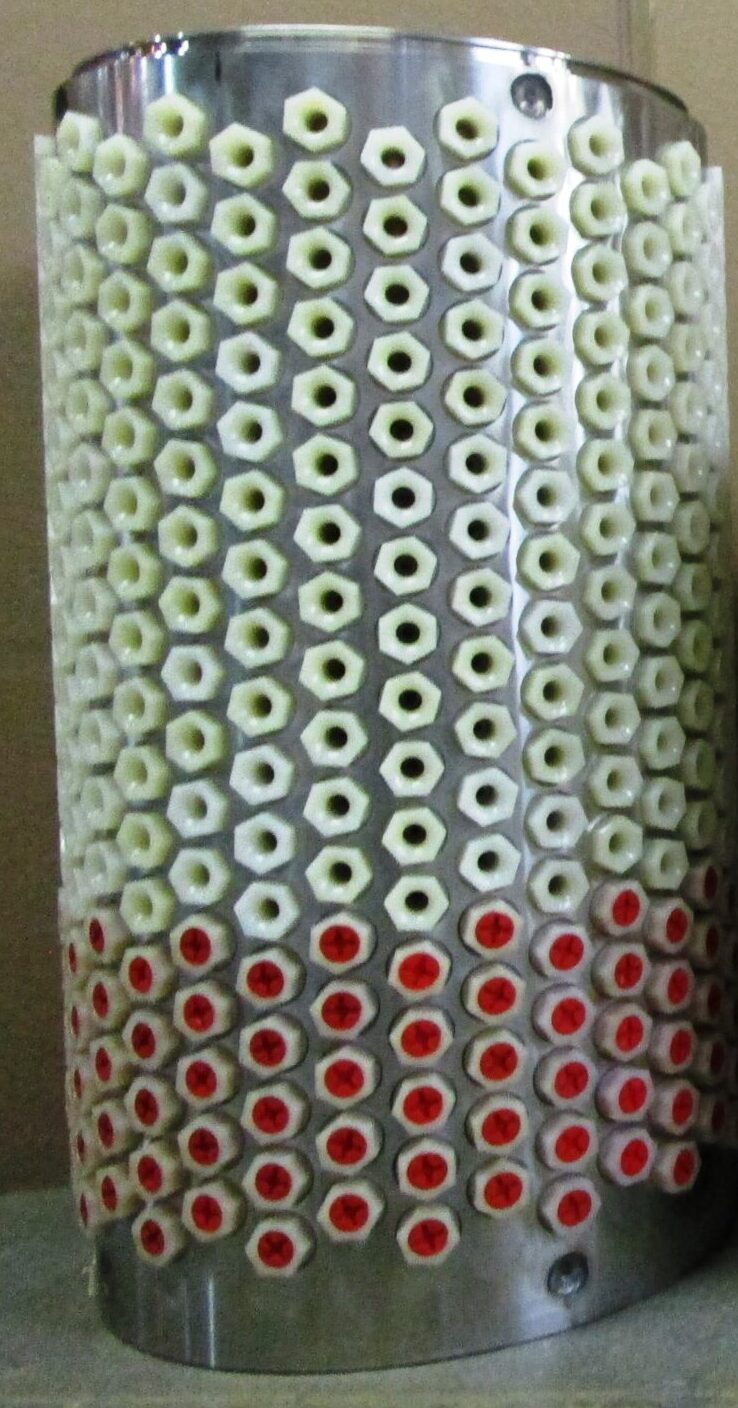

Cyclonettes are mounted between two concentric stainless-steel cylinder cartridges that form three separate chambers including, feed slurry, underflow stream, and overflow stream.

The number of cyclonettes can be changed with customized cartridge sizes.

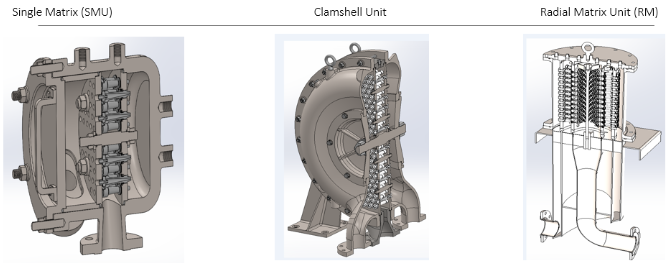

Matrix Options

Single Matrix Unit shows simple design with ease of maintenance access.

12 Stage Starch Washing with Radial Matrix Units. Mezzanine installations are an option for a 12-Stage Starch Washing Systems.

Cyclonette Geometry

Cyclonettes have a conical interior chamber with an inlet (feed hole) in the edge of the large end (base) of the cone and outlet holes in the centers of the small end (apex) and of the base. Because the feed hole is tangential to the curve of the interior surface, slurry introduced under pressure through the feed hole begins spinning smoothly around the cone’s surface toward the small end.

Spinning action creates centrifugal forces on slurry, causing heavier (higher specific gravity) particles and liquids (blue spiral) to migrate outward, closer to cone’s interior surface.

As slurry spins toward apex, decreasing available space forces inner, lighter portion (red spiral) of slurry to reverse direction and travel back toward and through overflow outlet at base.

The outer portion of the slurry flow continues toward the apex and through underflow outlet.

Principles of Starch Washing

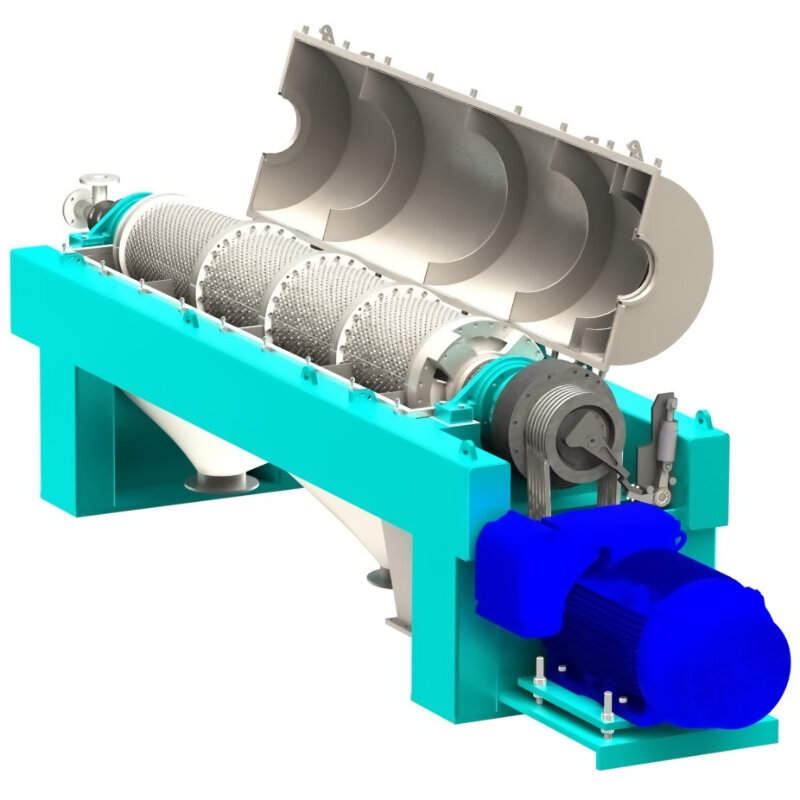

The goal of starch washing is to separate starch particles from soluble and insoluble proteins. Starch washing units can contain a variable number of Cyclonettes (small cyclones) that function as centrifugal separation devices. Cyclonettes are mounted across two parallel stainless-steel discs within a stainless-steel case to form three separate chambers for feed slurry input and for underflow and overflow output streams.