Applications

Benefits

Solves Plugging Problems

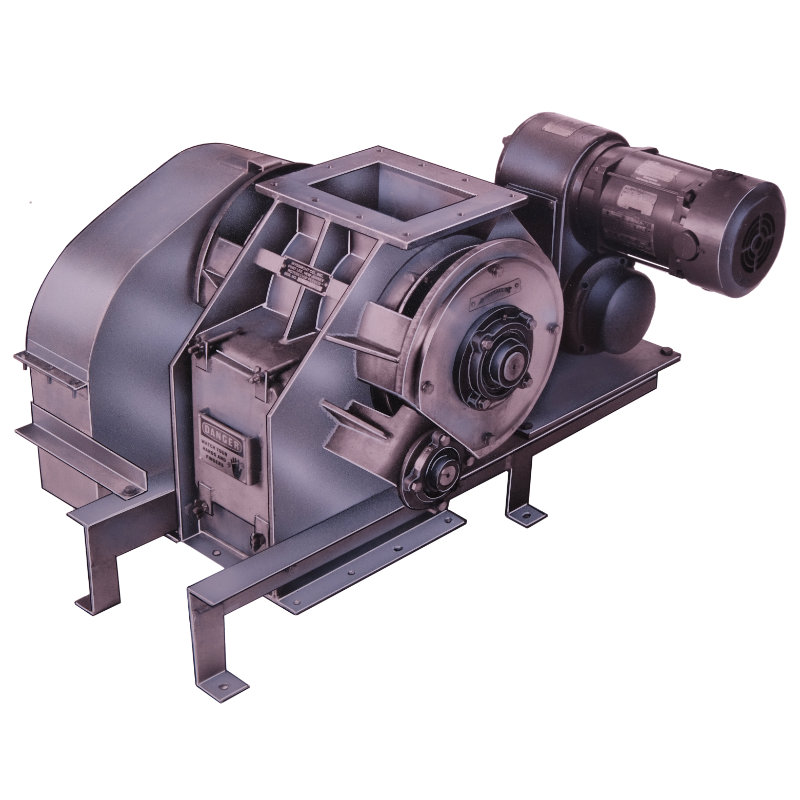

The Rotoscoop Airlock Feeder is specially designed to handle wet, sticky materials such as filter cakes, wet crystals or powders, pastes, and sludges. This feeder solves the problems caused by wet, sticky feeds plugging the feeder. Fumes or vapors from a reactor can also cause dry free-flowing materials to become moist and build up on an airlock, so that the process has to be stopped to clean the airlock. This feeder can solve the problem of slight, gradual build-up causing reduced capacity.

Accurate Feeding

The rotating cleaning blades are synchronized to sweep every pocket on each revolution to assure that the pockets of the feeder will remain free of material build-up. This feeder is able to obtain accuracies as fine as ½%, depending on the material.

High Capacity Design

The Rotoscoop Airlock Feeder is specially designed to handle wet, sticky materials such as filter cakes, wet crystals or powders, pastes, and sludges. This feeder solves the problems caused by wet, sticky feeds plugging the feeder. Fumes or vapors from a reactor can also cause dry free-flowing materials to become moist and build up on an airlock, so that the process has to be stopped to clean the airlock. This feeder can solve the problem of slight, gradual build-up causing reduced capacity.

Standard Features

- Totally enclosed variable AC motor

- Mechanical variable speed drive

- Drive guards

- Friction overload clutch

- Inspection door – access to cleaning blades

- Safety interlock on access door

Optional Features

- Explosion proof or Chemical duty motor

- DC motor with SCR variable speed controller

- AC motor with VFC variable speed controller

- Safety interlock on drive guards

- PTFE non-stick coating

- Feed hopper

- Purged bearings or shaft seals