Applications

Related Products

Benefits

How does it work?

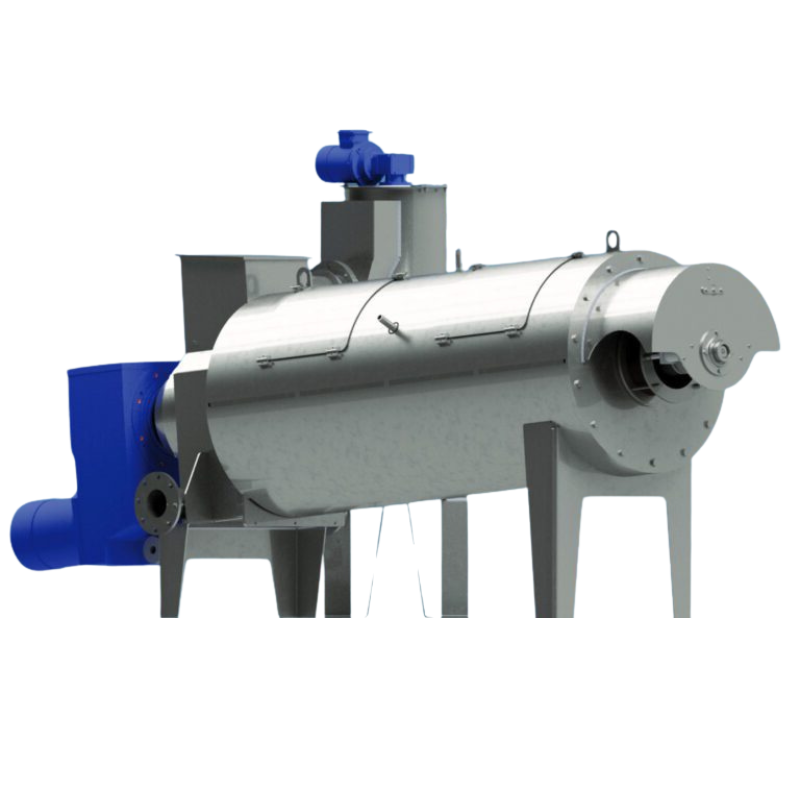

The process of the RDVF is continuous. Each revolution of the drum consists of cake formation, cake washing (if needed), dewatering or drying, and cake discharge.

- As the drum rotates, it is partially submerged in the feed slurry.

- Vacuum draws liquid through the filter medium (cloth) on the drum surface which retains the solids. Vacuum is applied using a liquid ring vacuum pump or other means.

- The vacuum pulls air (or gas) through the cake and continues to remove moisture as the drum rotates.

- Finally, the cake is discharged from the drum to a conveyor or chute to the next process step.

- The filtrate and air pulled through the medium flow through internal filtrate pipes and pass though the rotary valve and into the filtrate receiver.

- The liquid stream is separated from the vapor stream in the receiver.

- Liquid filtrate is then pumped to the next step in the process.

If required, the cake can be washed to remove impurities or to extract more product. Additional drying of the cake follows washing.

How do I know if an RDVF is right for my process?

If your process involves any of the following, then the Komline-FluidQuip RDVF may fit your needs.

- Continuous separation of solid and liquid

- Solid or Liquid Product recovery

- Clarification of liquid product

- Cake washing for cake purity or liquid product extraction

- Clarification of a wastewater stream

Our equipment requires minimal operator attention as well as low maintenance time and expense and is designed and built for long equipment life.

If you can relate to these objectives, then follow these steps:

- Establish process inlet and outlet conditions as accurately as possible

- Complete the FluidQuip Applications Questionnaire

- Contact us to assist in making a preliminary selection

- Perform lab and/or pilot scale testing if necessary

- Make final selection

Other important considerations:

- What is immediately upstream and downstream of the filter?

- What is most important: cake solids, filtrate clarity, capital or operating cost, etc.?

- What have you tried before? Why did/didn’t it work?

- What materials of construction are acceptable? What are not?

- Do you need auxiliary equipment?

- Do you need any instrumentation or controls?

- Do you have any standard specifications?

There are many factors affecting the operation of a filtration process. Among these are the need for chemical pretreatment; the need for precoat or filter aid; power, water, air, or other utilities; operator attention; cleaning requirements; and maintenance needs. All of these should be considered when selecting a filter.

System Benefits

The RDVF offers

- Continuous operation

- Application versatility

- Ease of operation, requiring minimal attention

- Simple, durable design for low maintenance and long life

- Wide Range of Sizes

Komline-FluidQuip has been a leader in liquid/solid separation equipment design and manufacturing for over 60 years, meeting the needs of both industrial and municipal clients. Our filters operate worldwide in an ever-growing range of process and wastewater applications. Expert process insight, outstanding customer service and high quality equipment make Komline a valuable partner throughout the project cycle.

Lab and pilot testing service is available to assist in equipment selection and sizing. Testing is also used to determine cake washing needs or other operating aspects.

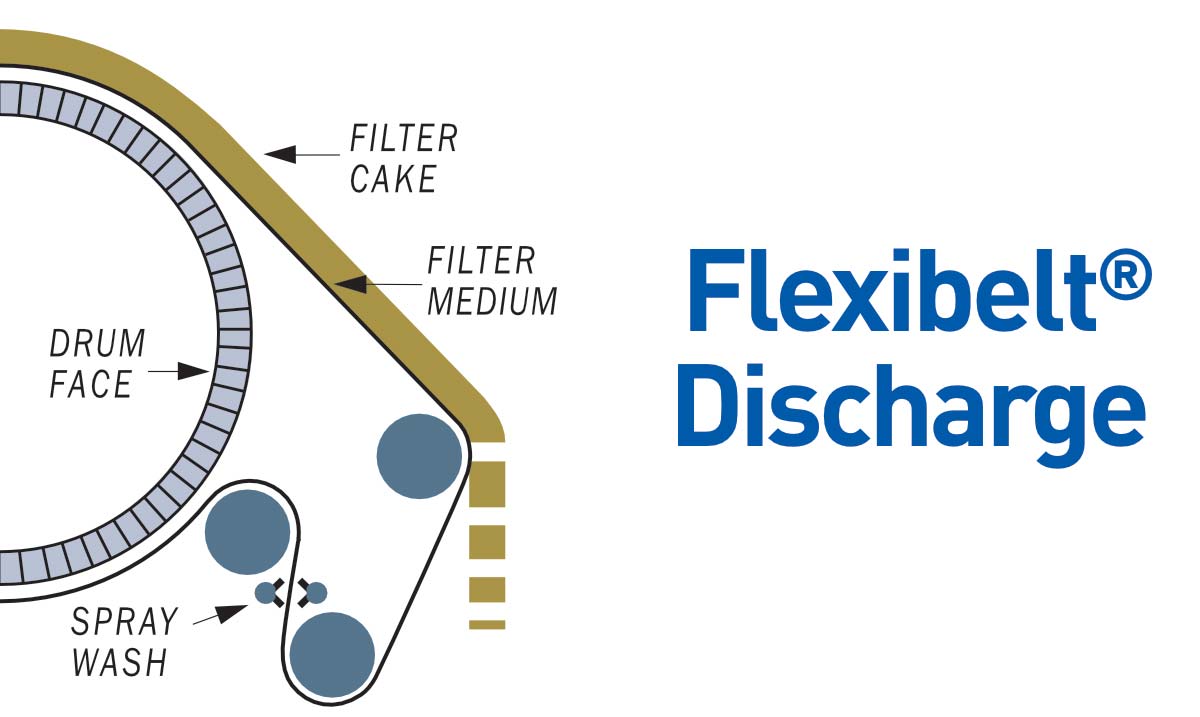

Flexibelt Discharge

The Flexibelt® discharge features a filter belt that passes over a variable speed discharge roll with raised helix for positive cake removal. It is typically applied:

- Where filter medium washing is required to prevent blinding.

- For the discharge of thin cakes.

- For dry cake discharge or sluice (wet) cake discharge.

Typical Flexibelt® Discharge Applications

- Corn Gluten

- Starch

- Pharmaceuticals

- Fermentation Broths

- Pigments

- Organic/Inorganic Chemicals

- Water Softening Sludge

- Steel Mill Waste

- Hydroxide Sludge

- Industrial Wastewater

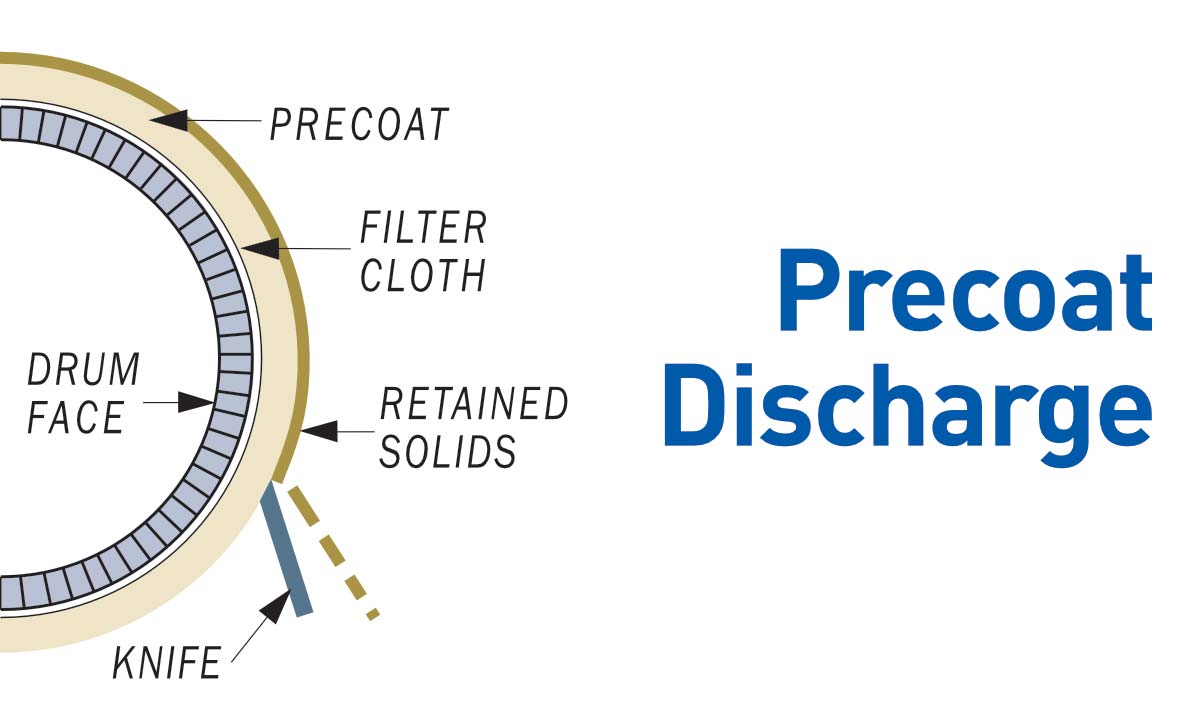

Precoat Discharge

The Precoat discharge is used when direct filtration against a cloth medium is not possible because the cake cannot be removed from the cloth or when blinding is indicated. It is typically used:

- For slimy, sticky, oily and blinding solids.

- For clear filtrates.

- For filtering dilute slurries with varying feed concentrations.

- For the discharge of very thin filter cakes.

Typical Precoat Discharge Applications

- Corn Syrup Clarification

- Fruit Juices and Wines

- Pharmaceuticals

- Fermentation Broths

- Food Processing Wastes

- Hydroxide Sludge

- Slop Oil

- Flexographic Ink Wastes

- Industrial Wastewater

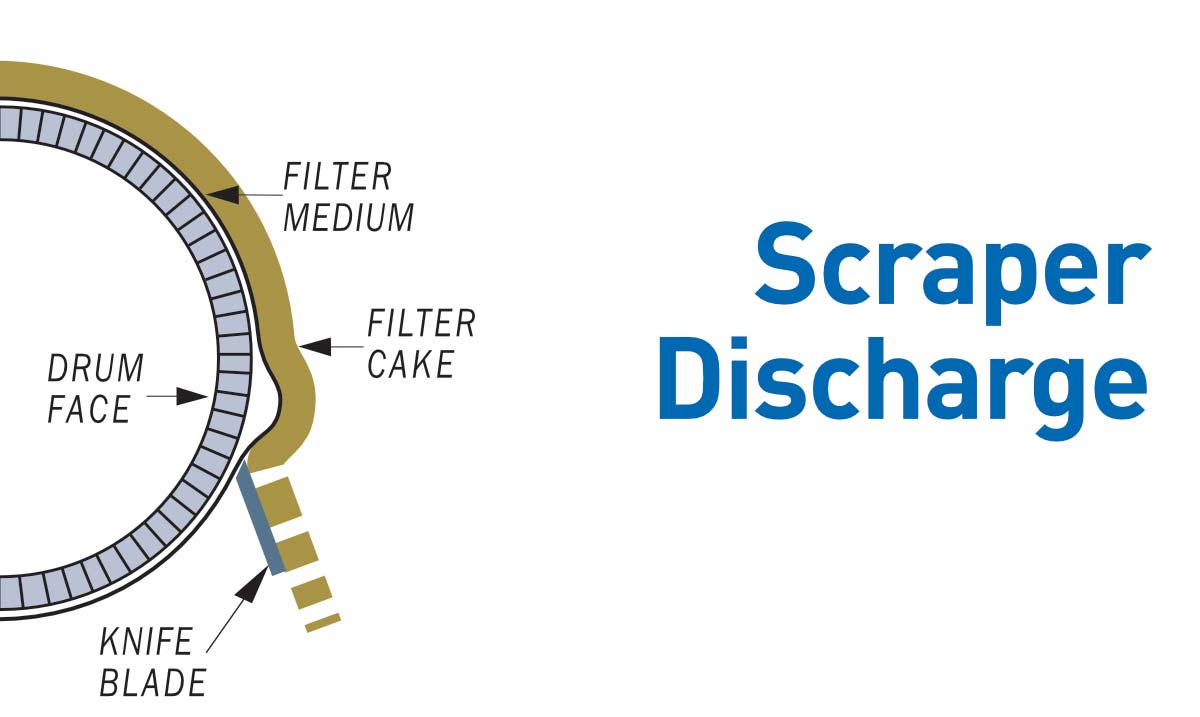

Scraper Discharge

Scraper discharge is usually used along with air blowback to release the filter cake from the cloth just above the scraper. It is used:

- For fast filtering materials.

- For filtering/dewatering granular or crystalline solids.

- For discharging cakes in excess of 1/4″ thick.

- For non-blinding cakes where cloth washing is not required.

Typical Scraper Discharge Applications

- Flue Gas Desulfurization (FGD) Scrubber Sludge

- FGD Gypsum Dewatering and Cake Washing for Wallboard

- Inorganic Chemicals and Minerals

- Pigment Processing

- Plastics Resins (Polymers)

- Calcium Compounds

- Titanium Dioxide

- Edible Oil Dewaxing

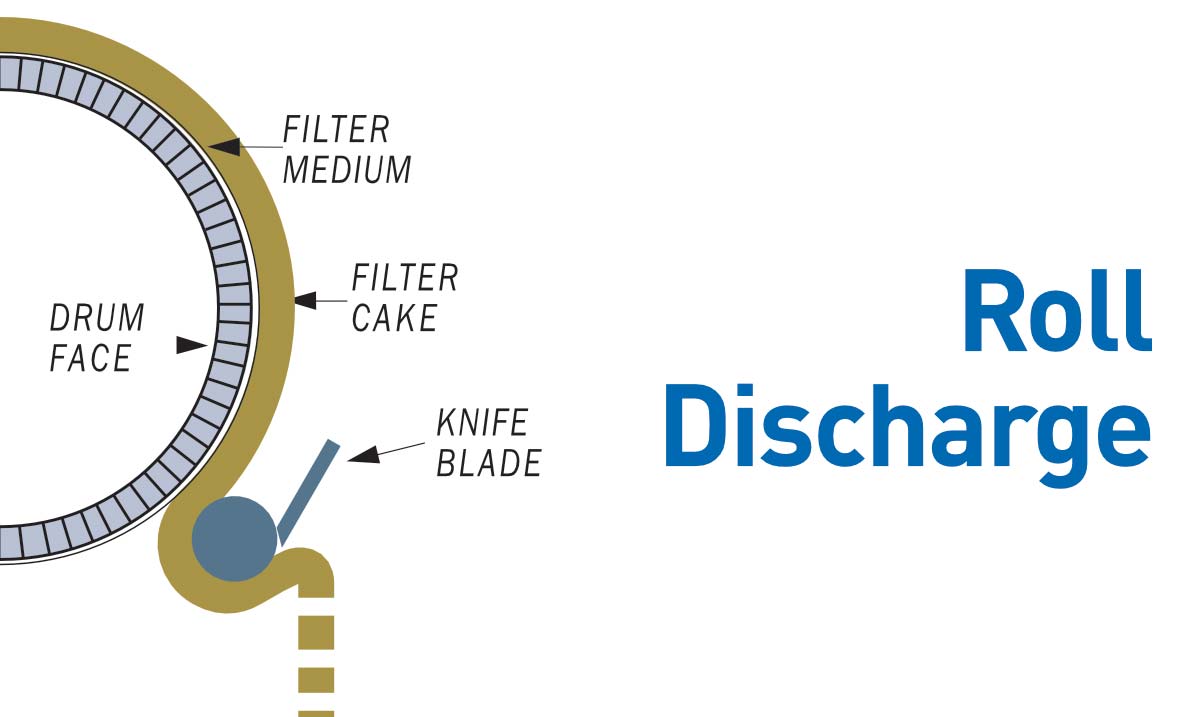

Roll Discharge

Roll discharge filter is usually fitted with a very tight filter medium to retain very small particles and is used:

- For discharging very thin, sticky (tacky) cakes.

- For discharging dilatent and thixotropic materials.

- For applications with very small particle sizes.

Typical Roll Discharge Applications

- Kaolin Clay

- Titanium Dioxide

- Pigments

- Ceramic Materials

- Magnesium Hydroxide

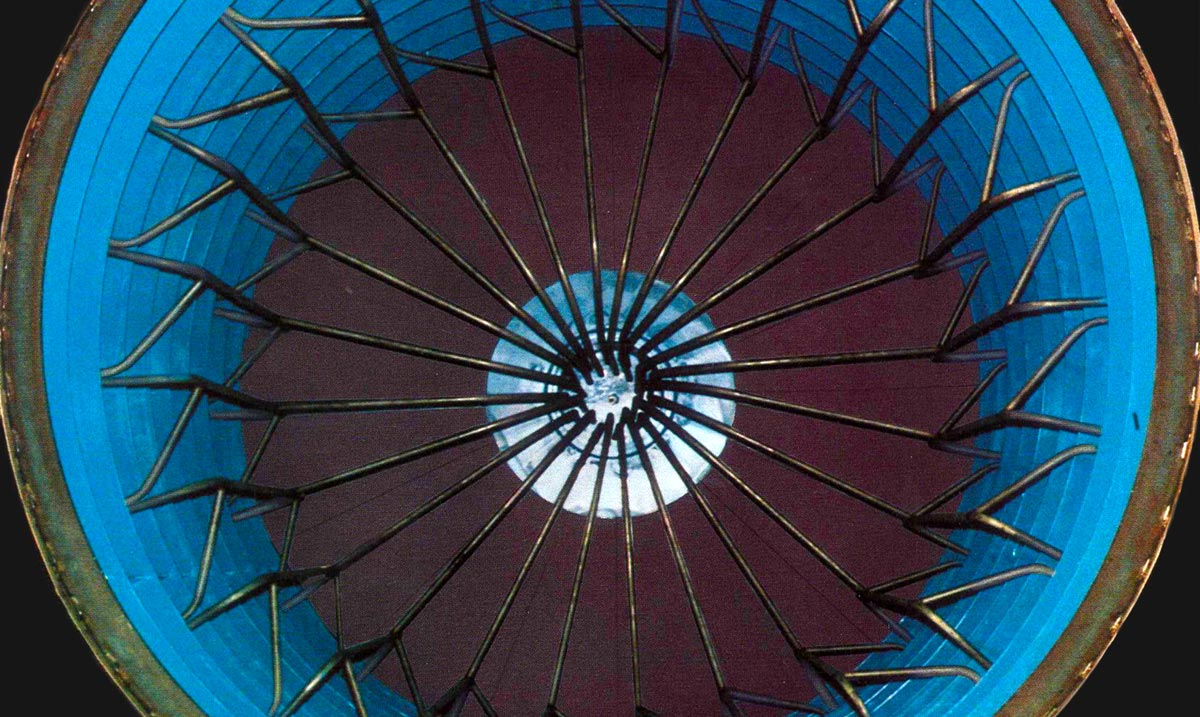

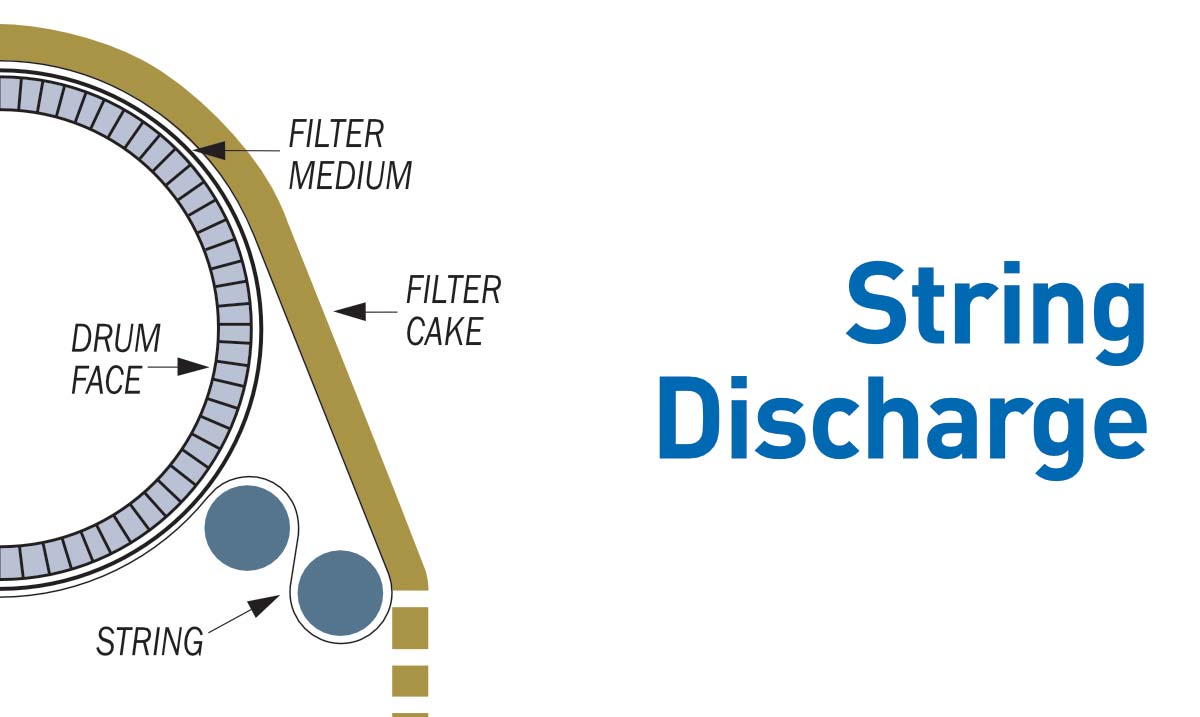

String Discharge

String discharge filters utilize closely spaced parallel strings to lift the cake from the cloth. The strings then pass over a discharge roll and the cake is released. Since no mechanical wear occurs to the filter medium, long life is assured. It is used:

- For discharging cohesive cakes.

- For discharging gelatinous cakes.

Typical String Discharge Applications

- Starch

- Fruit Juice

- Fermentation Broths

- Mineral Processing

System Features

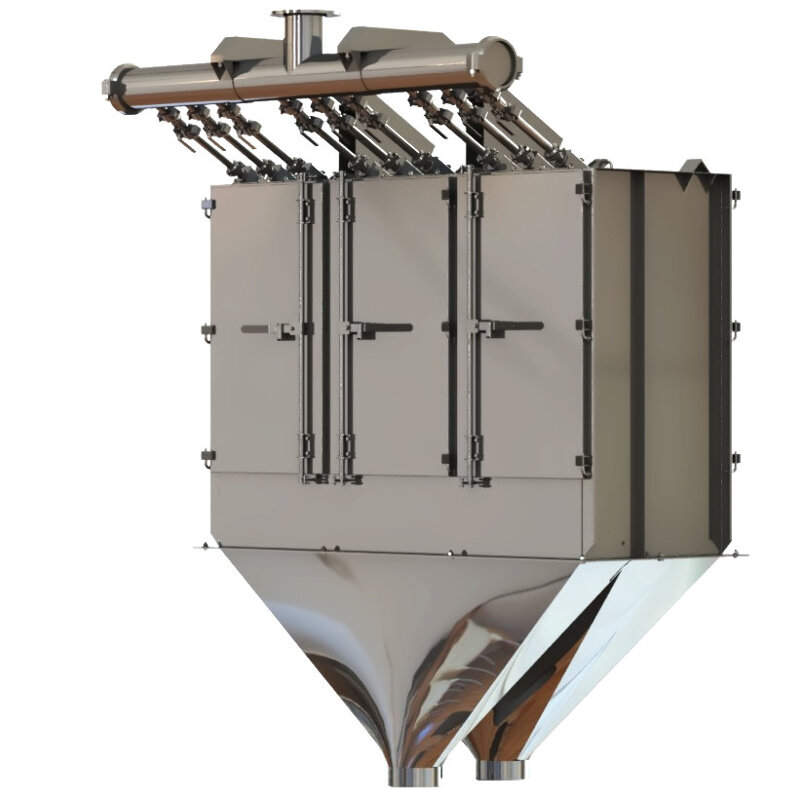

The project engineers provide assistance at all phases of the project. Depending on your specific requirements and can provide you with a Rotary Drum Filter or a complete system.

A successful plant depends on the integration of the key process units with properly selected ancillary equipment and the right facility design. Reliability, ease of operation, rugged construction, performance, and superior customer service are all trademarks of a Komline-FluidQuip installation.

A typical system includes a vacuum pump, filtrate pump, and vacuum/filtrate receiver. Also required in some cases are feed or drain pumps and precoat or chemical prep tanks with mixers. Often these items are mounted, wired and piped on a common base for ease of installation. Depending on customer needs, cake-handling equipment can also be provided. Controls and instrumentation are available to complete the system.

When necessary, our vapor tight design allows for the processing of material containing organic solvents and hazardous materials in an enclosed safe manner. Inerting of the process with nitrogen can also be accomplished with a minimal purge rate.

Q & A:

Q:

Can an RDVF be used in a batch process?

A:

Yes, although the filter operates as a continuous separation device, it can be used in batch processes. In these cases, the filter would be operated intermittently as needed to filter a batch of feed slurry.

Q:

When is cake washing used?

A:

Cake washing is used when a given cake purity is required. It is also used to improve extraction of liquid products or dissolved materials from the filter cake. Lab or pilot testing can be used to determine the effectiveness and efficiency of cake washing on an RDVF.

Q:

How is the correct size and style of cake discharge determined?

A:

Lab testing is often the best way to determine the correct filtration characteristics of a given material. In many cases, an RDVF has been previously installed or tested for the same or a similar application. This provides a good starting point in selecting equipment.

Q:

What designs are available?

A:

The design of the RDVF can be changed to suit specific needs for a given application. Various types of cake discharge mechanisms are used depending on the characteristics of the filter cake. Our equipment can be constructed of a variety of materials including carbon steel, stainless steel, plastic, Hastelloy, or titanium. Special material finishes for food or pharmaceutical applications can also be specified.

Q:

What if my process produces hazardous vapors?

A:

Designs are available for applications requiring vapor containment. Vapor-retaining hoods can be used much like the hood in a lab. Completely sealed, vapor-tight designs are used where absolutely no leakage is permitted.

Q:

What other auxiliary equipment is needed?

A:

Generally, items required are vacuum pump(s), filtrate pump(s), and vacuum/filtrate receiver. Also required in some cases are feed or drain pumps and precoat or chemical prep tanks with mixers. Depending on customer needs, cake handling equipment can also be provided. Auxiliary equipment can be provided by Komline-FluidQuip for a complete system including controls and instrumentation

Q:

What utilities are required?

A:

Electric power is required to run the filter drives as well as the vacuum pump and the filtrate pump. Water is needed as seal liquid for the vacuum pump and also for cloth wash and sometimes cake wash depending on the application.

Q:

How much operator attention and maintenance are required?

A:

The RDVF is essentially a hands-off machine that requires very little operator attention. Also, it runs at a very slow speed (typically between 0.25 to 1.0 rpm). This means that it will generally operate trouble free with very little maintenance. Maintenance usually involves lubrication of drives and bearings and occasional changing of filter cloth and replacement of wear items.

Q:

How much do spare parts cost?

A:

It is difficult to give a specific cost since there are many sizes and designs of RDVFs, however, spare parts costs are generally low on a yearly basis. Replacement filter cloth is the most common spare part. Other items requiring yearly maintenance include certain wear items on the filter valve and the cake discharge assembly.

Q:

What technical service is available?

A:

Technical service is available for installation and start-up of new equipment. Existing units can also benefit from a service visit to assist in optimizing performance. Contact us for a service proposal.

Q:

Are pilot filters available?

A:

RDVF pilot units are available for rental. The filters have 316SS wetted parts and can be fitted with a cake discharge assembly suited to the application.