Applications

Related Products

Benefits

Design Features

- Precise manufacturing tolerances and G1 balance specifications on all rotating components minimize machine vibration, ensuring smooth, worry-free operation, extended bearing life, and reduced maintenance costs.

- The robust frame and motor support are engineered to ensure structural stability and minimize machine vibration.

- Belt driven machine design

- Dual flanged feed inlets with flanged cleanout ports

- Standard foot mounted motors

- Vibration switch with internal alarm/shutdown limits

- Continuous oil lubrication system

- Large discharge hopper with flanged outlet

- When used alongside pressure screens and paddle screens, a single FQ-IM40H Impact Mill can process up to 40,000 barrels per day (1,000 metric tons per day).

Third Grind Disc Mills Vs. Impact Mills

- Less energy consumption per unit of grind rate

- Less fine fiber generation in the product slurry

- Lower overall bound starch in fiber

- Increased starch yields

- Optimal machine performance is maintained across a wide range of capacities and feed conditions without requiring operator adjustments.

- Maintaining consistent machine efficiency and product quality throughout the lifespan and wear cycle of the impact pins. Experiences less temperature increase, reducing the risk of starch gelatinization.

- Smaller motor sizes required

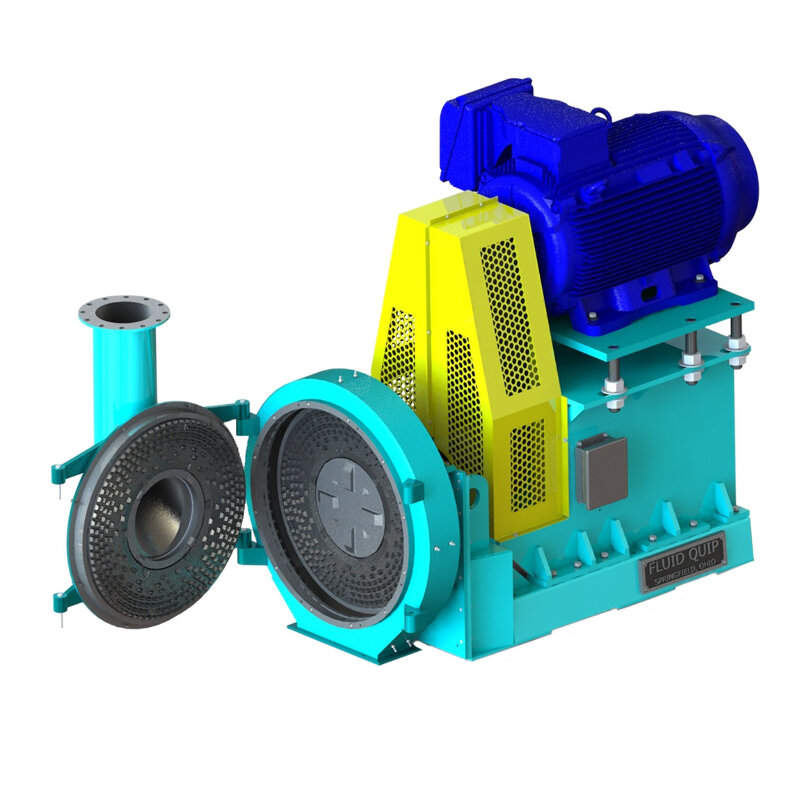

FQ-IM40-Impact-Mill

- The FQ-IM40 Impact Mill is designed for third grind operations, utilizing up to 300 horsepower through a belt drive system.

- Featuring a horizontally rotating 40-inch rotor lined with 3-inch long impact pins, ensuring efficient separation of bound starch from fiber particles while minimizing the reduction of fiber particle size.

- The smaller FQ-IM40 Impact Mill can handle capacities of up to 24,000 barrels per day (600 metric tons per day).

FQ-IM40H-Impact-Mill

Our FQ-IM40H Impact Mill is engineered for third grind operations, utilizing up to 600 horsepower through a belt drive system. The mill features a horizontally rotating 40-inch rotor lined with 3-inch-long impact pins, ensuring efficient separation of bound starch from fiber particles while minimizing the reduction of fiber particle size.

The FQ-IM40H Impact Mill can handle capacities of up to 40,000 barrels per day (1,000 metric tons per day).

Impact Mill Retrofit

Do you have an older machine that needs updating? A re-manufactured machine provides the same performance and reliability as a new Impact Mills. By utilizing the existing frame and maintaining the original footprint, this approach can lower piping and mounting expenses and potentially reduce manufacturing costs. Once rebuilt, the new Impact Mill will accommodate all FluidQuip's replacement parts, reducing maintenance costs and enhancing dependability.