Applications

Benefits

Reliable Oil Separation

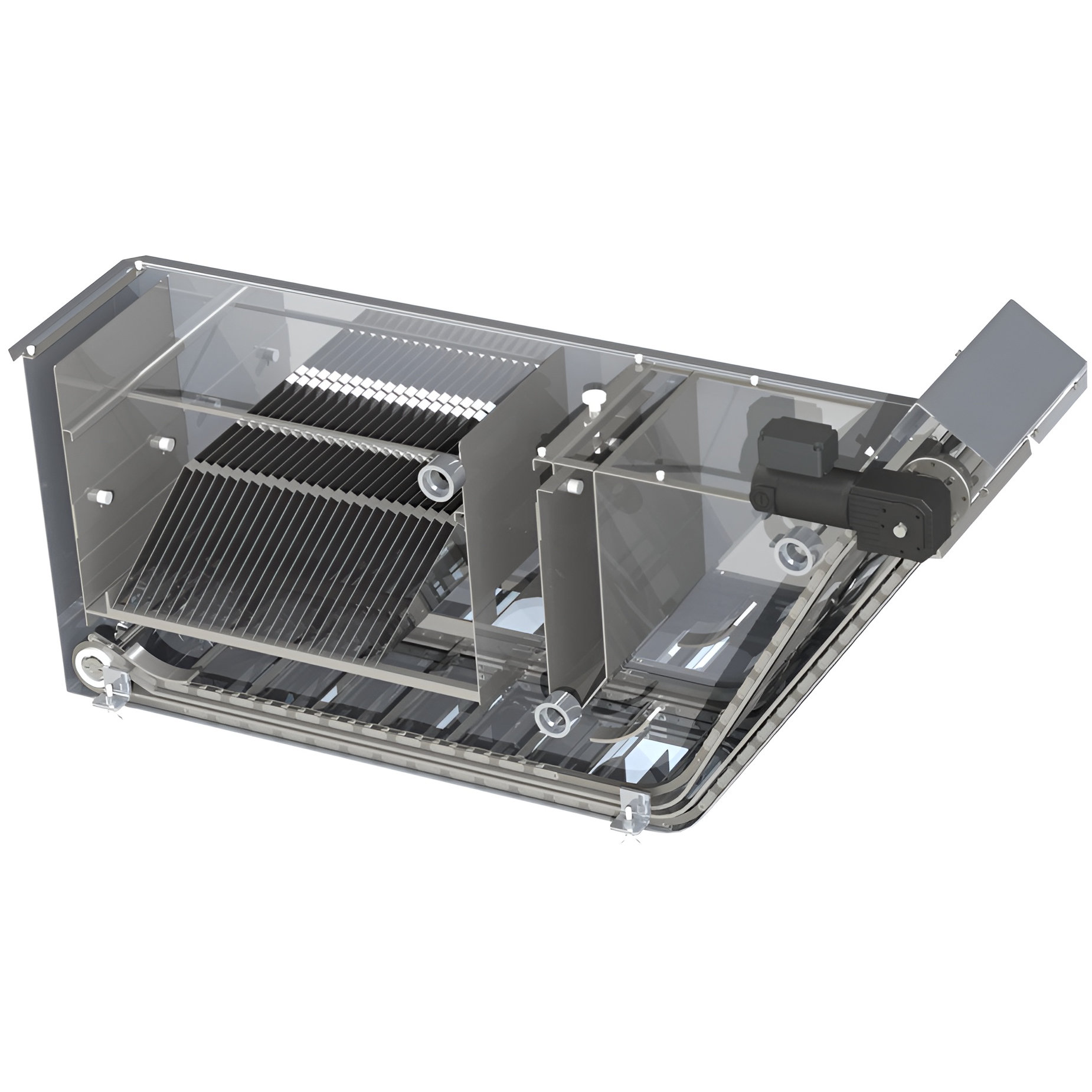

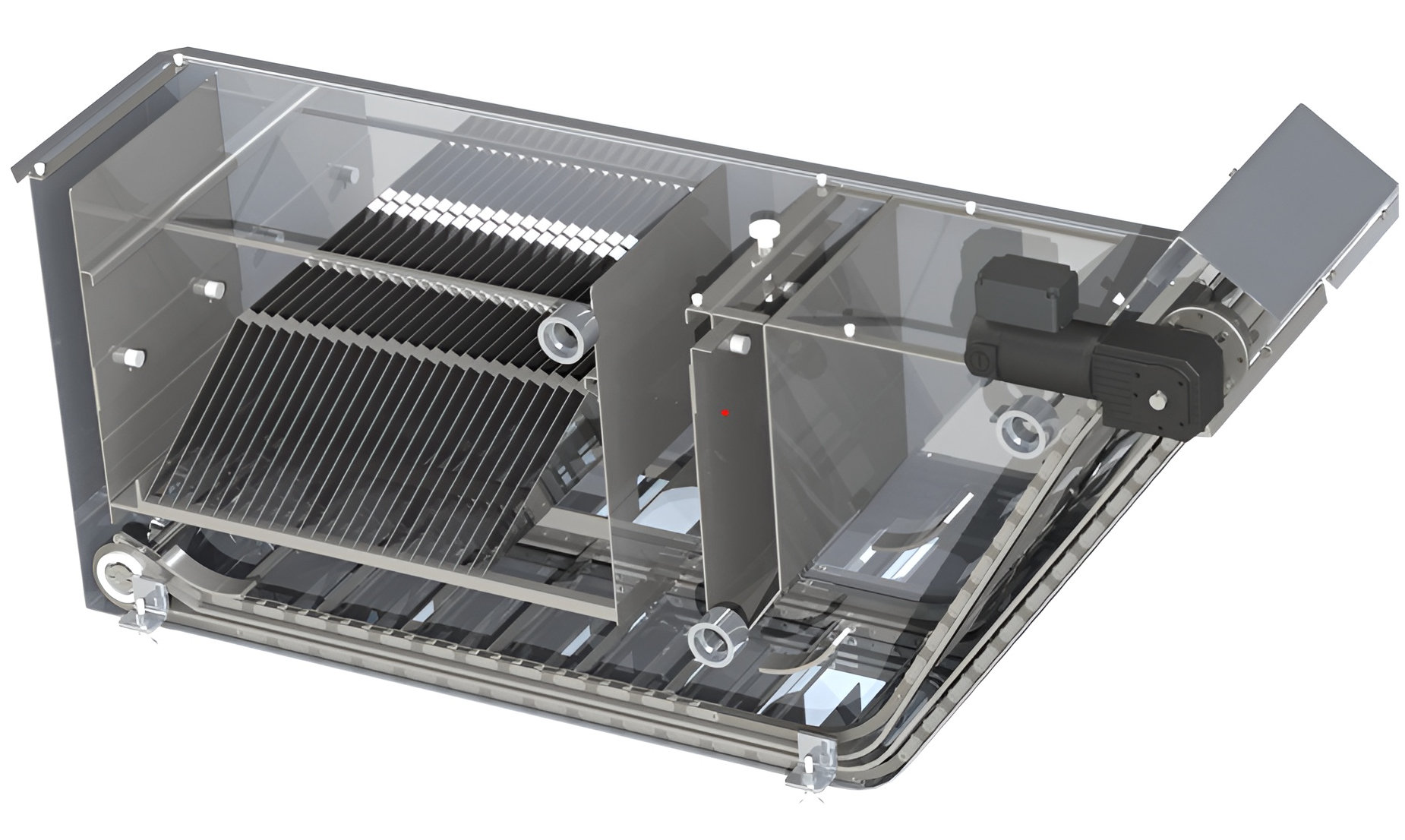

The main problem with oil separation systems is dealing with floating solids like aluminum chips, sediment, and/or cast-iron grinding swarf. Competitive systems tend to plug at the difficult-to-clean areas; skimmer head, pump suction pipe, and inside the decant tank. Solutions:

- The H.O.S.S. was developed to eliminate plugging at the skimmer float suction supply tube

- The H.O.S.S. system has easily removable coalescent plates for ease of cleaning

- The optional conveyorized system will remove any solids that settle to the bottom of the decant tank

Features & Benefits

- Robust stainless steel tank construction for a long service life

- Low maintenance for lower operational costs

- Extends the life of industrial coolant fluids and wash solutions by effectively removing tramp oil

- Level seeking, non-plugging ball float skimmer pick up head

- A reliable pump transfers skimmed surface oil to the oil separation decant tank

Optional Features

- Pump suction pipe backflow design eliminates plugging at the floating suction head (Electric Pump Option)

- Solids and sludge that have settled to the bottom of the oil separation decant tank are removed by a chain and flight conveyor (optional)

- Level switches and electrical controls

- Holding tank for removed tramp oil

- Tramp oil tank discharge pump

- Additional options upon customer request

Basic Operation

- The level-seeking skimmer head (ball float assembly) skims the surface of the liquid inside the filter tank

- An air-operated diaphragm or electric centrifugal pump draws the liquid through the suction piping and discharges it into the oil separation decant tank

- The oil and coolant solution are separated using a uniquely designed decant tank with laminar plates

- The separated oil is then gravity discharged into a waste container and the clean, processed fluid is gravity discharged back to the filter tank

- Suspended solids that settle to the bottom of the decant tank will be conveyed out through the discharge chute (on conveyorized units only)