Applications

Benefits

Technology

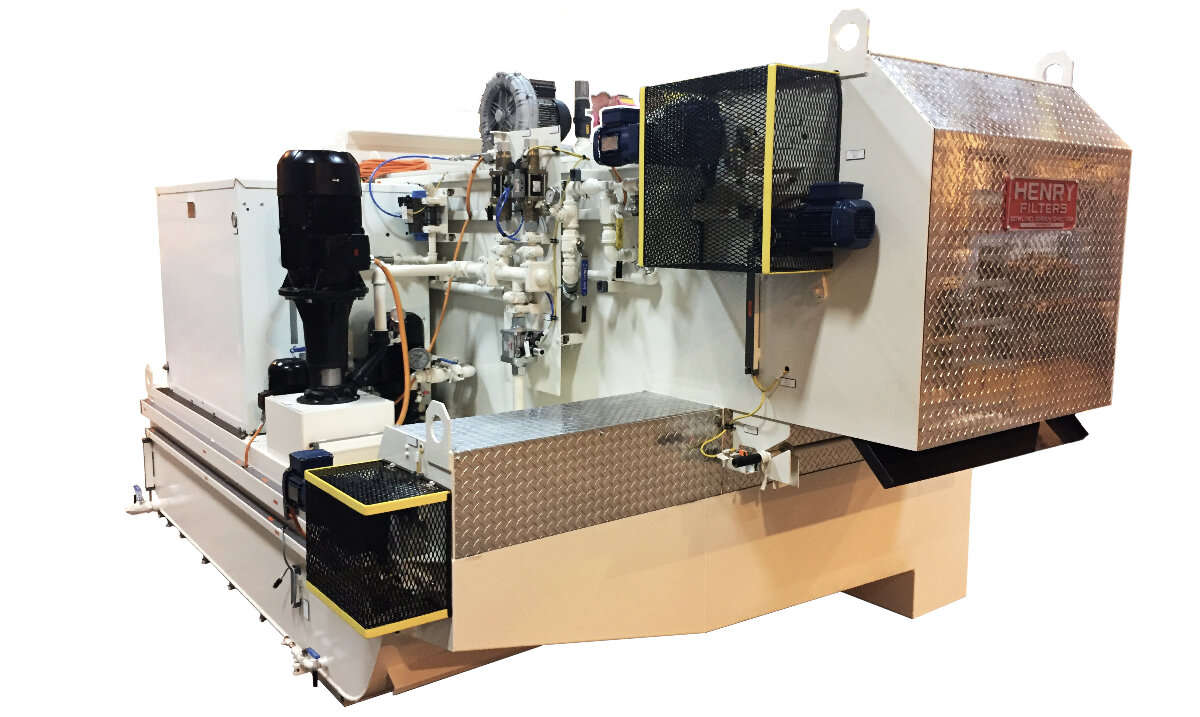

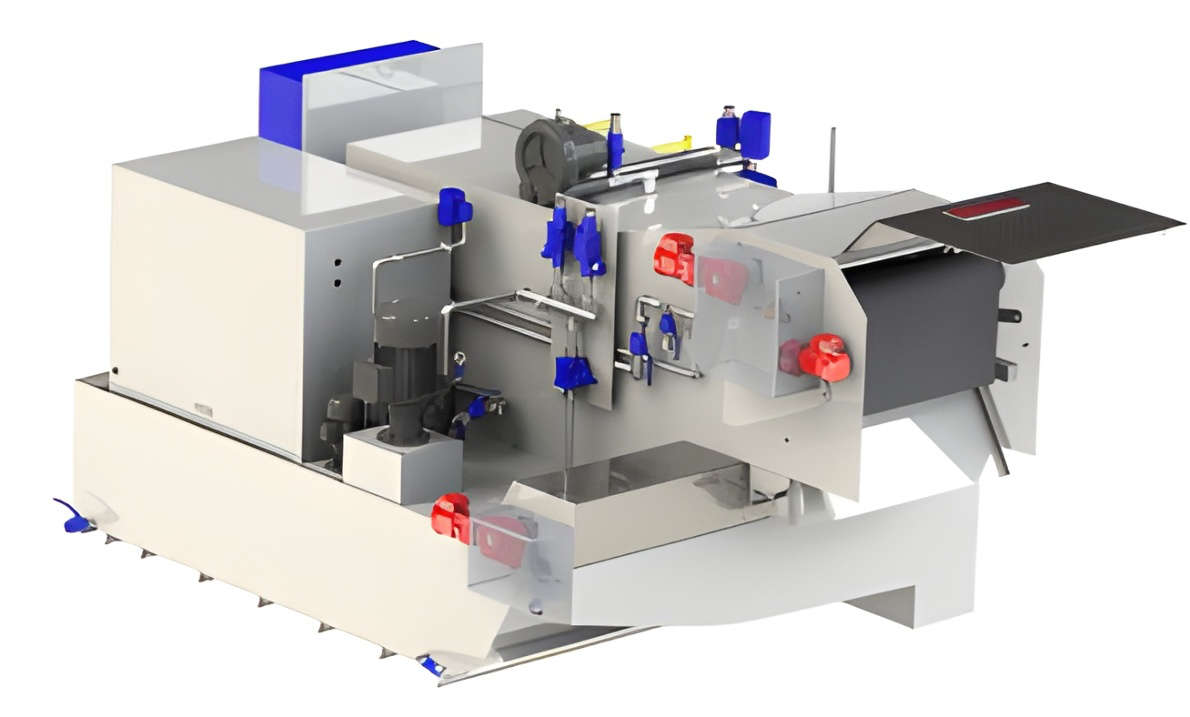

The Henry DTVF filtration system, with SealTrack™ positive mechanical seals, provides high-clarity filtration for grinding applications. The SealTrack™ mechanical seal technology is a means of incorporating a positive side seal on the filter belt, or disposable media, throughout the path within the filter tank. The filter belt is attached to a roller/ hookchain on each side, used for transport/ indexing. This eliminates flight contact and premature wear. This proven technology stays in place during the filter cycle, thus virtually eliminating the potential of chip bypass. With this side sealing system, additional secondary backup filtration is not necessary. In addition, the DTVF incorporates a vacuum drying area, that pulls excess fluid from the swarf, before it is discharged into the chip tote. Another unique feature of the DTVF is the conveyorized clean tank, eliminating the need for cleanout doors.

Process

Contaminated fluids enter the side of the dirty return sump and are pumped to the dirty fluid reservoir, above the suspended vacuum box. This area remains full and overflowing to the lower dirty tank, where a continuously operating drag conveyor, reintroduces the fines to the dirty return sump, to be reprocessed. Fluids in the dirty reservoir are then drawn through the filter belt, or disposable media, to remove the fine particulate. The clean fluid is sent to a separate clean tank, that is also conveyorized to be used in the machining/grinding and auxiliary process, as well as in The filter index cycle. A high velocity blower is used to remove access fluid from the swarf that has accumulated on the filter belt. The DTVF also utilizes a driven polypropylene brush, to remove dry swarf from the belt.

Filtration/Index Cycle

As the filter operates, the fine particulate is drawn to the suspended vacuum box, this causes a chip cake to build on the filter belt, or disposable media. As the filter cake increases, the flow to the filter/ system pump is restricted, causing the filter to index. The index cycle can be initiated by this restriction (vacuum switch) or a timer. The filter pump then stops, allowing vacuum on the filter belt/ disposable media to be released, and a new section of clean belt/ media is introduced. As the media belt advances, a high velocity blower

is activated, to remove excess fluid from the swarf. After completion, the filter pumps restarts, allowing normal operation, drawing fluid thru the filter belt/ media.

Media Options

The DTVF filter can operate using permanent media (polyester or polypropylene) belt or with disposable media. Permanent filter belts are available down to 10 micron, based on application. Disposable media can be used on top of the permanent media for occasional removal of tramp oils or sub-micron fines. It can also be used continuously where a “carrier” belt will be used to transport the disposable media. Either belt allows for easy installation onto the DTVF’s roller/ hook chain. A typical filter belt takes under 30 minutes to install.