Applications

Benefits

Minimize Heat & Fines

Unlike hammer mills, pin mills, or other lumpbreakers, the Rotocage Lumpbreaker does not generate heat or create fines by overworking the material. In most cases screens are not needed.

Large Variety Of Rotor Designs

A variety of cage designs are available to meet each application. Square bars are the standard used for most applications. Cutter bars can be used when a chopping or shredding action is required. Round bars are used to avoid breaking or damaging pellets and crystals. Heavy square bars are used for heavy-duty applications on harder materials.

The sturdy bars of the Rotocage are welded to the rotor assembly in at least three places. Therefore, while fingers or pins can break off and enter your product stream, the bars of the Rotocage stay intact.

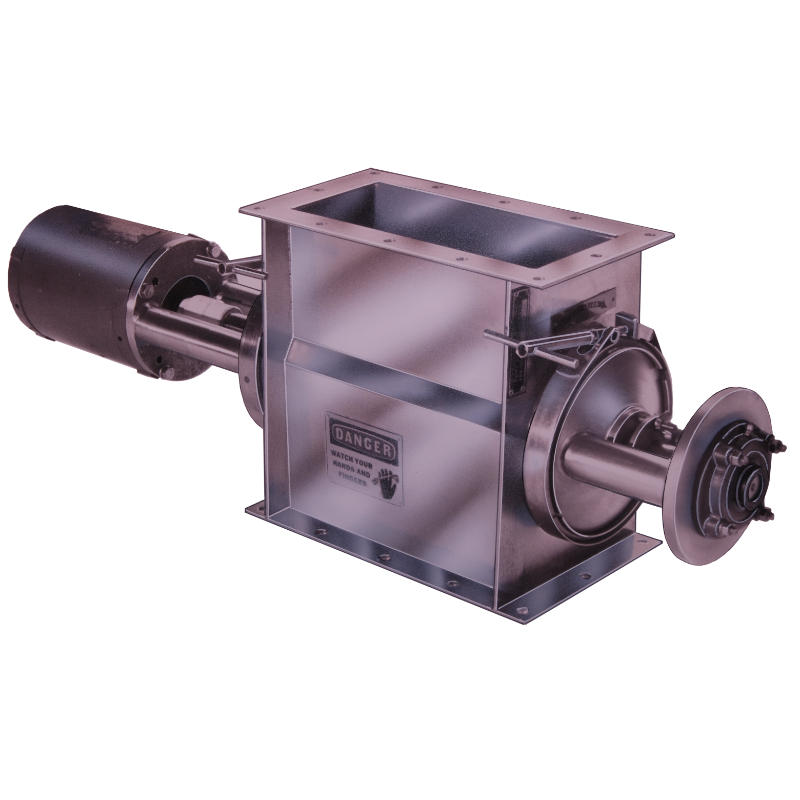

The Rotocage Lumpbreaker is available in stainless steel, carbon steel, and special alloys.

Dimensions can be modified as necessary to match flanges of existing equipment or to fit into tight spaces.

Standard Features

- Variable pitch pulleys, V-belt drives

- Totally enclosed AC motor

- Drive guard

- Adjustable sizing gate

Optional Features

- Heavy duty construction

- Variable speed drive (AC or DC)

- Sizing screen

- Support stand (to fit over 55 gallon drum)

- Feed hopper

- Outboard bearings & stuffing box shaft seals (add 5″ to “D” dimension)

- Purged bearings or shaft seals

- PTFE non-stick coating

- Hard-facing or abrasion resistant coating

- Safety interlock on drive guard