Applications

Related Products

Benefits

Benefits

Suspended Air Flotation (SAF®) is an advanced water treatment technology that offers highly efficient removal of suspended solids. SAF creates optimal results with reduced OPEX. Highest Removal Rates (TSS & FOG)

- Highest Removal Rates (TSS & FOG)

- Lower Energy Consumption

- Lower Chemical Use

- Supports Sustainability and Net-Zero Goals

- Thickest Solids (up to 8%)

- Compact Footprint

- Resilient to Load Changes

- Manages Changing Water Conditions

- Low Maintenance

- Operator Friendly

- Fast Start Up & Shut Down

- Continuous and Batch Processing

Design Features

- Suspended Air® Flotation Generator: Core technology for high-efficiency solids and oil removal

- ClearFloater®: Flotation tank for separation and collection

- ClearMixer®: Integrates froth with effluent to aid in flotation

- Chemical Dosing Systems: For coagulants, flocculants, and pH adjustment

- Polymer Dilution System with Aging Tank: Ensures proper polymer conditioning

- Flock Tubes: Facilitates mixing and reaction of polymers, coagulants, and pH agents

- Control Panel and Automation: PLC-based system for streamlined operation and integration

- Sludge Handling Equipment: Includes solids pump; solids often dewatered via gravity

- Flow Meters & Sensors: Monitor flow to support accurate chemical dosing

- Skid-mounted systems: Plug-and-play flexibility to speed startup

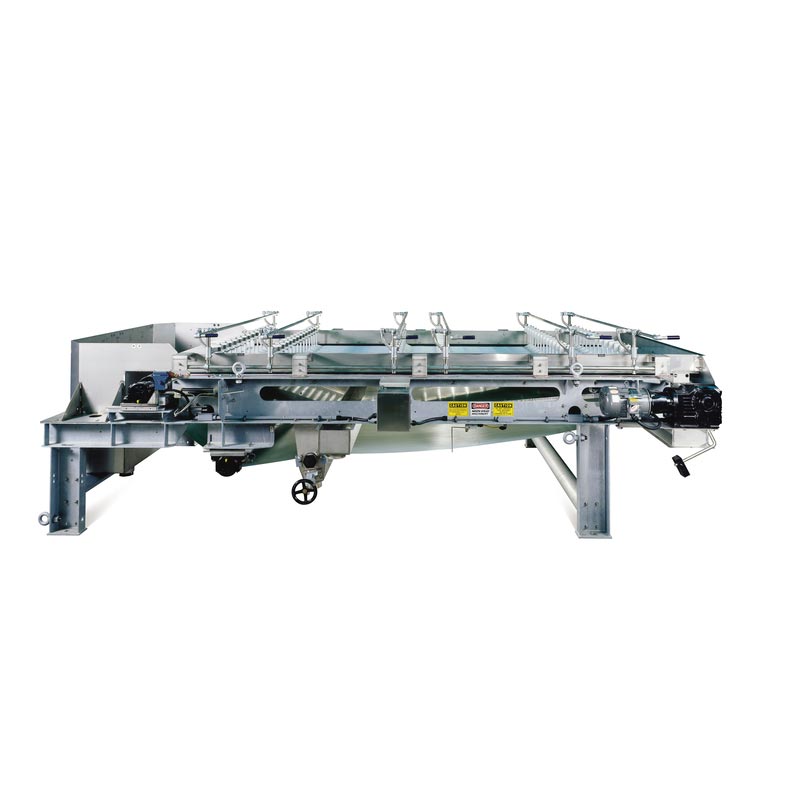

Skid-Mounted Systems

Fully-integrated, custom engineered, and skid-mounted SAF® water and wastewater treatment systems for industrial and municipal markets. Systems are self-contained and plug-and-play. They only require power, effluent, and a small amount of fresh water to operate. Startup is a matter of hours, not days. The efficiency of a skid-mounted SAF system is unparalleled. As pictured, the CF125 has a float surface area of 17 ft2 and treats up to 350gpm. Skid-mounted SAF® systems treat from 20 to 1,400 gpm. These systems are ideal for batch processing as startup and shut down processes are simple and easy, flip a switch to start, auto-flush and turn off to shut down.

| Horsepower | ||||||||||||

| SAF® System | Flow Capacity |

Float Capacity |

Skid Size |

SAF® | Feed Pump |

Solids Pump |

||||||

| GPM | MGD | LPS | m³/D | BPD | ft² | m² | ft | m | hp | hp | hp | |

| CF25 / F25 | 50 | 0.072 | 3 | 273 | 1,714 | 5.0 | 0.5 | 7 x 14 | 2.3 x 4.6 | 3.8 | 1.0 | 2.0 |

| CF50 / F25 | 125 | 0.180 | 8 | 681 | 4,286 | 10.0 | 0.9 | 8 x 18 | 2.6 x 6 | 3.8 | 2.0 | 2.0 |

| CF125 / F25 | 350 | 0.504 | 22 | 1,908 | 12,000 | 17.5 | 1.6 | 9 x 24 | 3 x 8 | 4.0 | 5.0 | 3.0 |

| CF250 / F50 | 700 | 1.008 | 44 | 3,815 | 24,000 | 35.0 | 3.3 | 10 x 28 | 3.3 x 9.3 | 6.3 | 10.0 | 5.0 |

| CF500 / F100 | 1,400 | 2.016 | 88 | 7,630 | 48,000 | 72.0 | 6.7 | 12 x 35 | 4 x 11.6 | 9.5 | 15.0 | 5.0 |

| CF1000 / F200 | 2,800 | 4.032 | 177 | 15,260 | 96,000 | 144.0 | 13.4 | Not Skid-Mounted | 17.5 | 40.0 | 7.5 | |

| CF2000 / F400 | 6,000 | 8.640 | 379 | 32,700 | 205,714 | 300.0 | 27.9 | Not Skid-Mounted | 29.5 | 80.0 | 7.5 | |

| CF3000 / F400 | 8,000 | 11.520 | 505 | 43,600 | 274,286 | 400.0 | 37.2 | Not Skid-Mounted | 31.0 | 100.0 | 15 | |