Applications

Related Products

Benefits

Process

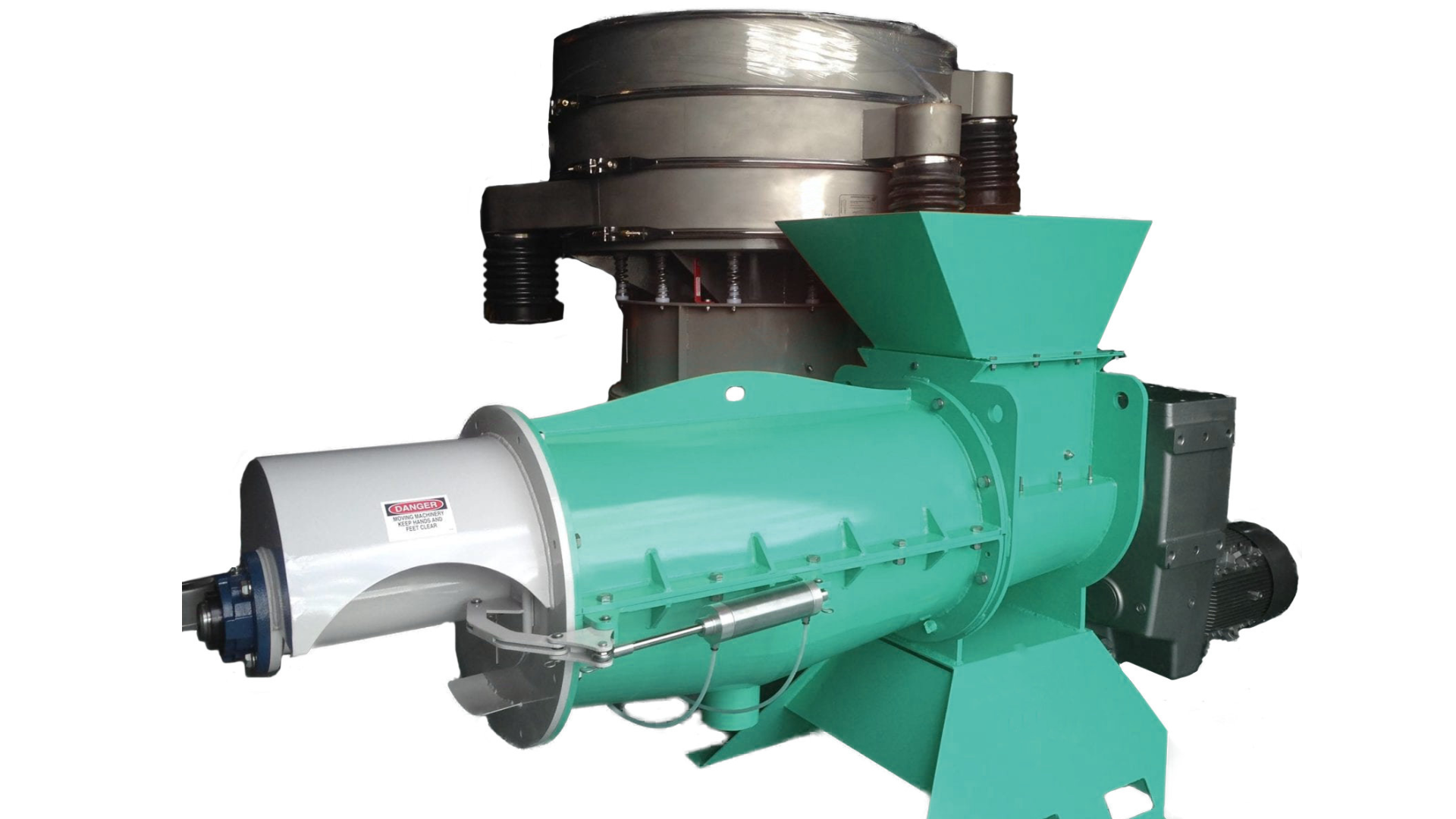

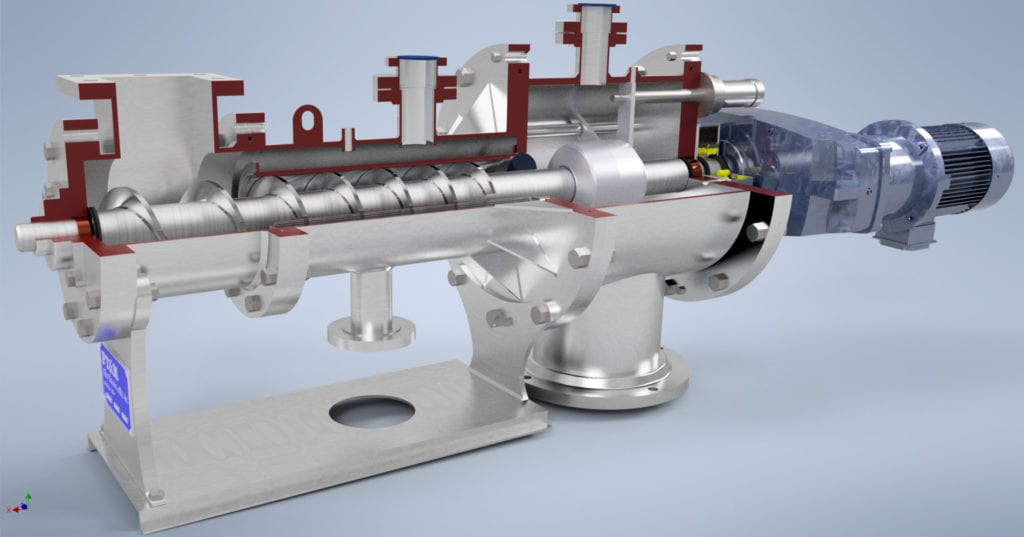

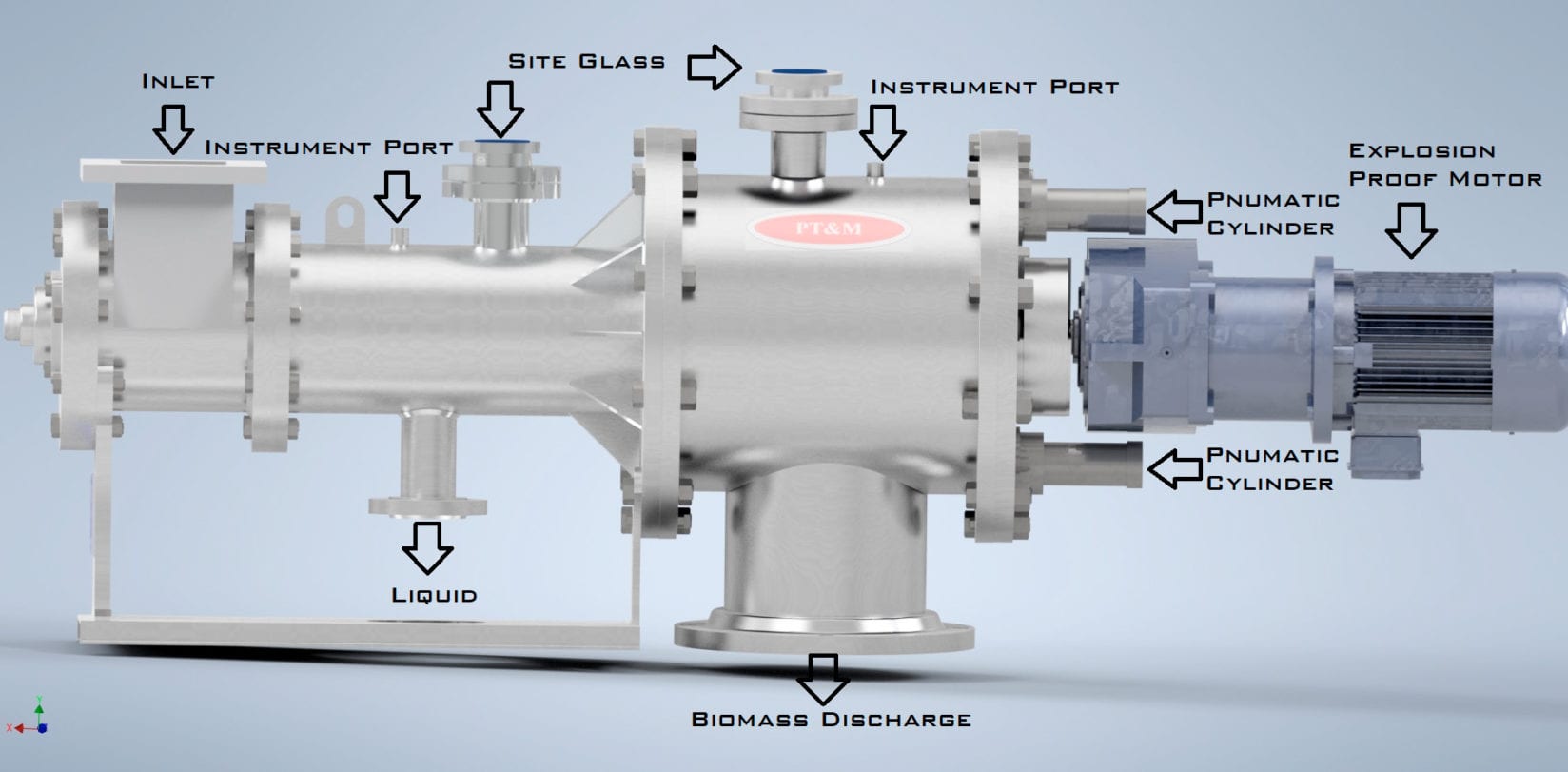

As material moves down the screw, free liquid drains away. At a specific point, the screw's volume decreases, applying pressure to extract the liquid. Air cylinders connected to a pressure plate (cone) create back pressure, further compressing the liquid. The air-driven cone ensures consistent dryness of discharge solids across a wide range, up to the mechanical dryness limit. Operators can adjust the pneumatic cylinders via a valve to achieve the desired dryness of the solids.

Design Features

- Standard 304SS Wetted Surfaces

- Available in 304 or 316 stainless steel

- Fully enclosed and pressure-tight up to 60 PSI

- Explosion-proof motor and controls

- Screen cage with wedge wire screens

- Various configurations and options available

- Capacity depends on material type and shaft RPM